CMG as the world leader in the design and manufacture of tie-rod cylinders, metric hydraulic cylinders are designed to meet the requirements of ISO, 160 Bar Compact Series. This Series cylinders may be used for working pressures up to 210 Bar.

Product Introduction

CMG as the world leader in the design and manufacture of tie-rod cylinders, metric hydraulic cylinders are designed to meet the requirements of ISO, 160 Bar Compact Series. This Series cylinders may be used for working pressures up to 210 Bar.

Hydraulic tie rod Cylinders/tie rod hydraulic cylinder

Standard Features and Specifications

• Wide range of mounting accessories

• Bore sizes – 25mm to 200mm

• Strokes – Non-standard strokes can be manufactured upon request

• Working pressure up to 210 bar

• Piston rods – 12mm to 140mm

• Single and Double rod designs

• Cushioning available at either end

• Temperature Range – -20°C to 150°C depending on seal type

• Seal types to suit a wide variety of operating environments

Piston Rod

Gland seal life is maximized by manufacturing piston rods from precision ground, high tensile carbon alloy steel, hard chrome plated and polished to max 0.2µm.

Gland

Continuous lubrication, and therefore longer gland life, are provided by the long bearing surface inboard of the primary seal.

Rod Seals

The TS-2000 primary seal has a series of sealing edges which take over successively as pressure increases, providing efficient sealing under all operating conditions. On the return

stroke the serrations act as a check valve, allowing the oil adhering to the rod to pass back into the cylinder. prevents the ingress of dirt into the cylinder, extending the life of gland and seals.

Cylinder Body

Strict quality control standards and precision manufacture ensure that all tubes meet rigid standards of straightness, roundness and surface finish. The steel tubing is surface finished to minimize internal friction and prolong seal life.

Piston Seals

Piston provides zero leakage under static conditions for hydraulic pressures up to 3000 psi. Seals are self-compensating to conform to variations in pressure, mechanical deflection, and wear. Back-up washers prevent extrusion. This design provides smooth operation, long bearing life, and high load carrying capacity.

Cylinder Body Seals

To make sure that the cylinder body remains leak tight, even under pressure shock conditions, utilizes pressure energized body seals.

Cushion Bushings and Sleeves

Closer tolerances – and therefore more effective cushioning cushion sleeve at the head end of the cylinder, and a cushion bushing at the cap end. A slotted cushion sleeve at the head end and the floating bronze cushion bushing in the cap, provide minimum fluid restriction at the start of the return stroke.

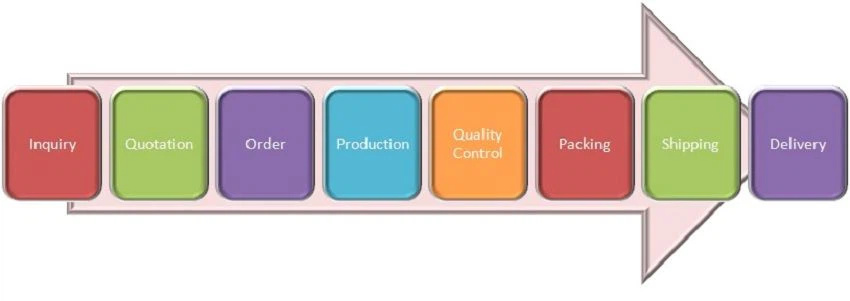

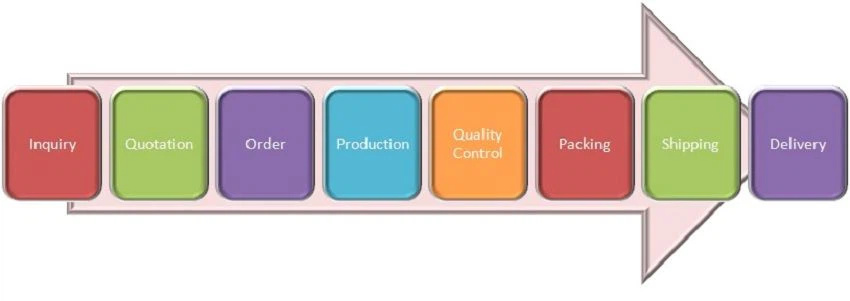

We can production all kinds of Metric Hydraulic Cylinders, Tie Rod Hydraulic Cylinders. Please send us your requirements. we can customized for you.

Or you can offer us your sketch diagram or photos so that we could understand your exact meaning, help us avoid mistakes.

We will supply you our best service and support. Your satisfaction is our biggest motivation.

Hot Tags: metric hydraulic cylinders, China, manufacturers, suppliers, factory, customized, buy, price, cheap, discount, for sale, Tie Rod Hydraulic Cylinders, Double Acting Tie Rod Hydraulic Cylinder, Hydraulic Tie Rod Cylinders, Tie Rod Cylinders, Tie Rod Cylinder, Tie Rod Hydraulic Cylinder