CMG offers double acting snow plow cylinders. CMG has professional R&D team with rich design experience and manufacturing capabilities.

CMG offers double acting snow plow cylinders.

Snow plow cylinder: If the cylinder fails to operate, you can start troubleshooting from these aspects:

(1) The hydraulic system control pressure is too low. The throttling resistance in the control pipeline may be too large, the flow valve is improperly adjusted, the control pressure is inappropriate, and the pressure source is disturbed. At this time, check the control pressure source to ensure that the pressure is adjusted to the specified value of the system;

(2) Air enters the hydraulic system. Mainly because there are leaks in the system. At this time, check the liquid level of the hydraulic oil tank, the seals and pipe joints on the suction side of the hydraulic pump, and whether the oil suction coarse filter is too dirty. If so, add hydraulic oil, deal with seals and pipe joints, clean or replace coarse filter elements.

(3) The initial movement of the hydraulic cylinder is slow. In the case of low temperature, the hydraulic oil has high viscosity and poor fluidity, which causes the hydraulic cylinder to move slowly. The improvement method is to replace the piston rod of the cylinder with better viscosity-temperature performance. If the piston rod is found to be worn, it can be brushed first, then ground, and finally adjusted the matching accuracy of the piston rod and the guide sleeve. At this time, the guide sleeve can be properly reamed or renewed. Car guide sleeve. When making the above repairs, remember to replace various rubber seals in time.

The hydraulic cylinder must perform multiple reciprocating operations with low pressure (greater than the starting pressure) before it works, and the air in the hydraulic cylinder can be discharged before it can work normally. Combination pads must be used to fasten the oil inlet and outlet ports and the joints to prevent oil leakage.

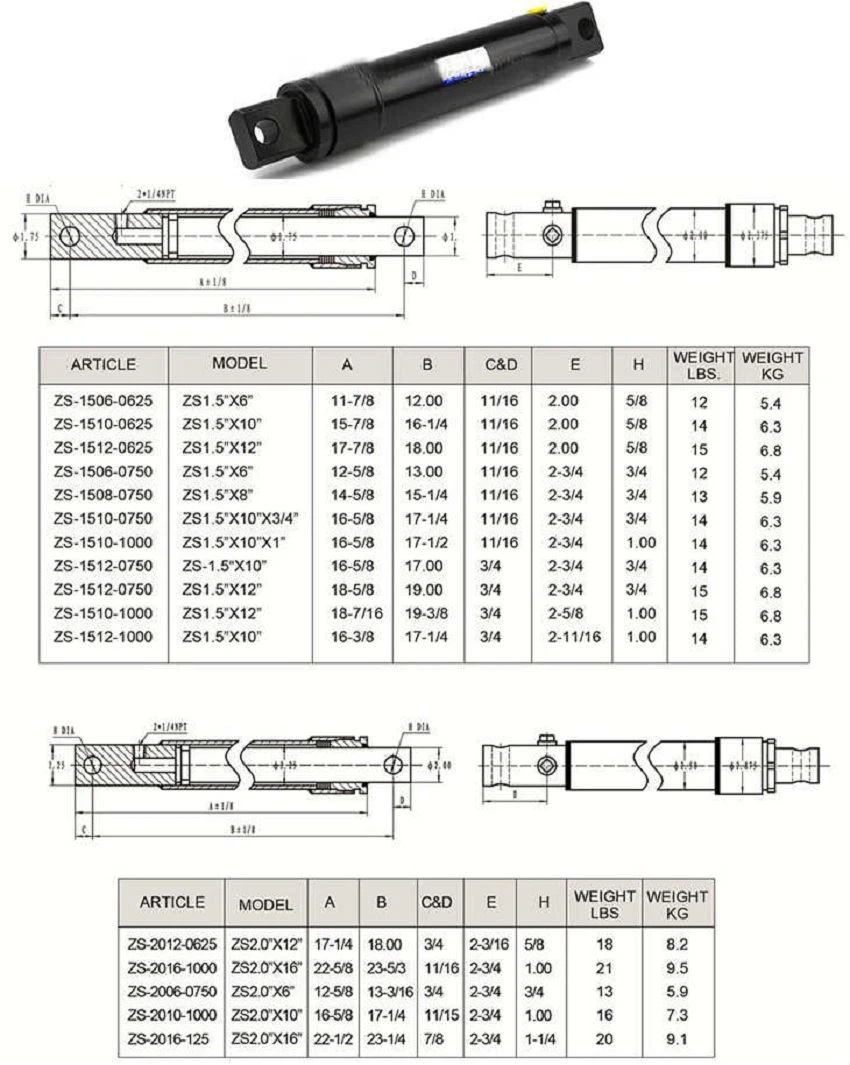

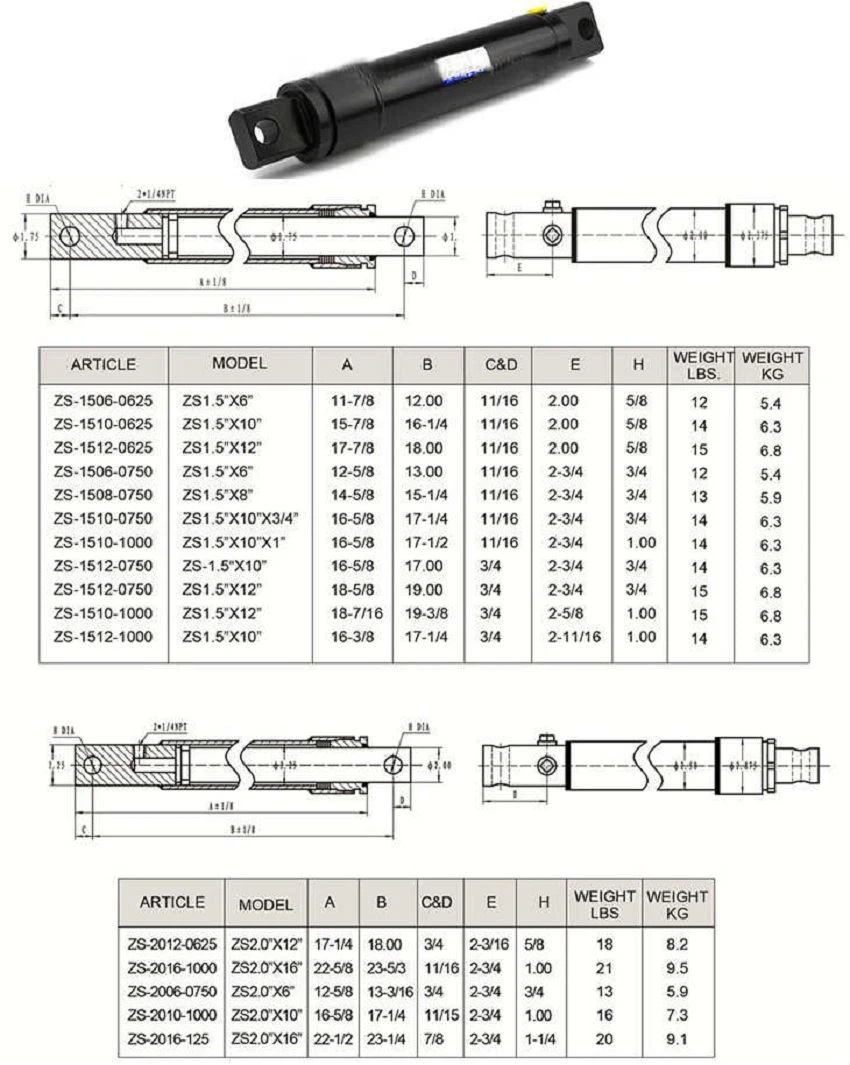

How To Measure Your Snowplow Hydraulic Cylinders?

Step 1: Count the number of ports of your cylinder

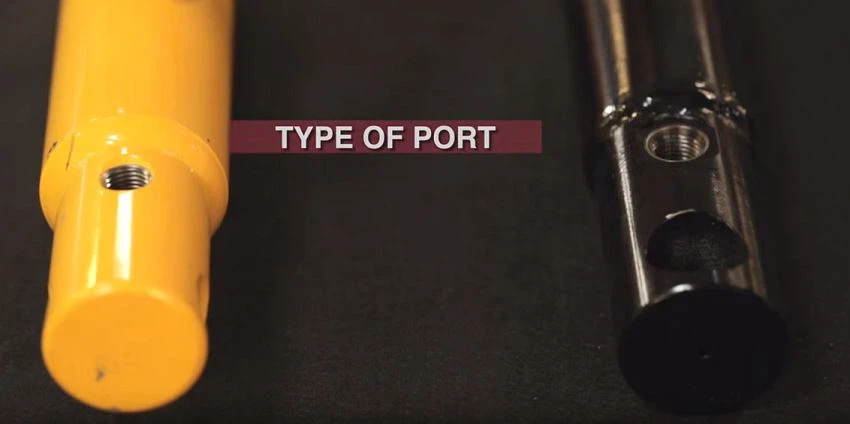

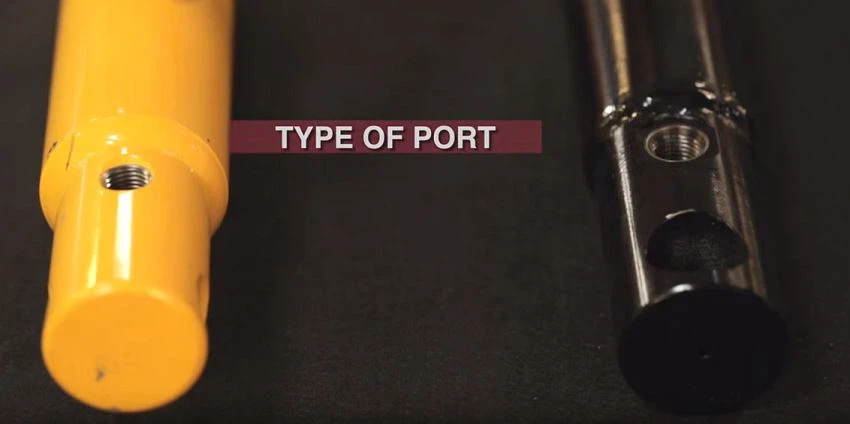

Type of port: One port is "Single-acting"; Two port is "Double-acting".

Single VS. Double

"Single acting" only have pressure one way while "double acting" extend and retract

Step 2: Measure the port size

Step 3: Identifying the ports your cylinder has

Type of port: You can either have a "Pipe thread" port OR a "Boss-O-ring" port

Step 4: Measure the retracted or "closed " length of your cylinder; Measure the extended or "Open-length" of your cylinder

From the center of one pin eye on the Dead-End(Base end) to the center of the pin eye on the Active end(Rod end)

Step 5: Calculate your cylinder "Stroke" or how much your cylinder moves

Step 6: Determine the mount and width of your cylinder (Cross tube, Drill through, Milled)

Measure the barrel diameter or the "outside" diameter of the cylinder and the rod diameter

Measure the "Dead-end" and "Active-end" of the pin diameter

FAQ

Can you give me a discount price?

It is depending on the quantity. The larger quantity the more discount you can enjoy.

Hot Tags: double acting snow plow cylinders, China, manufacturers, suppliers, factory, customized, buy, price, cheap, discount, for sale, Fisher Plow Angle Cylinder, Fisher Plow Lift Cylinder, Meyer Snow Plow Cylinders, Snow Plow Angle Cylinders, Western Snow Plow Cylinders, Western Plow Cylinder